Information Center

The Rise of AI Industrial Parks: Precision Manufacturing Leads the Way

Recently, the Zhongguancun Cuihu Science and Technology Park project of Beijing Urban Construction Northern Group has received in-depth focus and extensive coverage from many important media outlets, including the Capital Construction News, Beijing Youth Daily, Architectural New Network, China.com.cn, China Daily, Phoenix.com, and Huanqiu.com.

The Rise of the Artificial Intelligence Industrial Park: Ingenious Manufacturing Leads a New Chapter

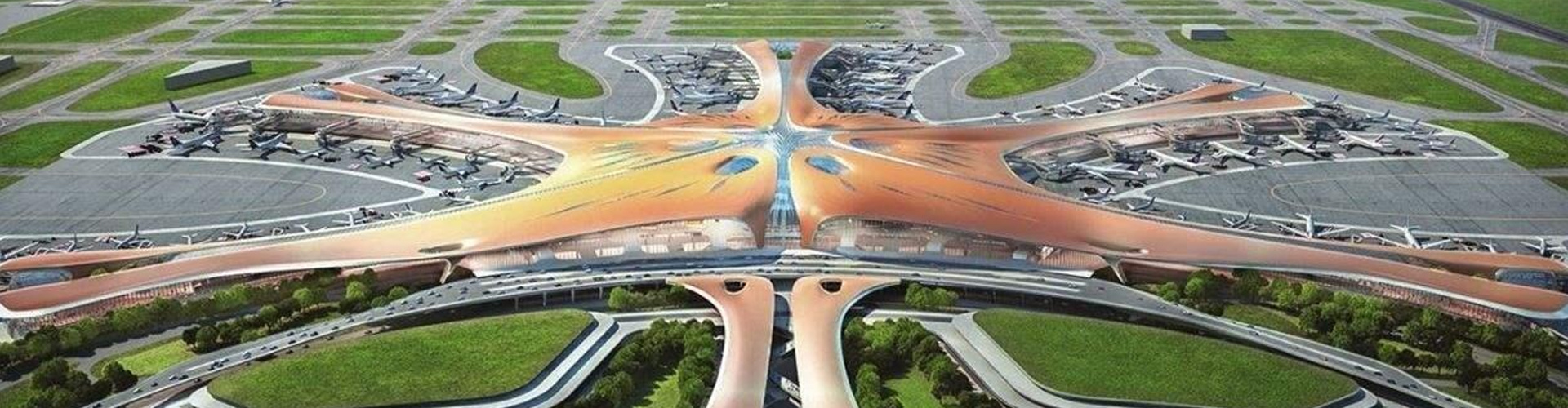

Approximately 1 kilometer from the Daoxiang Lake Road Station on Line 16 of the Beijing Subway, on a piece of land full of hope and vitality, a new park focusing on the artificial intelligence industry—the Cuihu Science and Technology Park Artificial Intelligence Innovation Application Pilot Zone—is flourishing.

The project has a total construction area of 500,000 square meters, covering research and development land, multifunctional land, and park green spaces. It aims to create a high-quality, integrated science and technology park combining research, office, and commercial services. Upon completion, it will become a powerful engine driving technological innovation in Haidian District and even Beijing, attracting and cultivating a group of high-tech enterprises with international competitiveness, forming a cluster effect in the artificial intelligence industry, and injecting new vitality into the development of new productive forces.

The Li Shuo team of Beijing Urban Construction Northern Group undertook the construction of 131,300 square meters of this project. Among all the sections constructed by the four construction companies competing on the same platform, the section managed by Li Shuo's team was the first to complete the structural topping-out.

Winning Strategy: Construction of a Refined Industrial Park Product Line

“Our project's Building 1 was the first to achieve topping-out. This achievement is due to the project team's in-depth application and practice of the Group's industrial park product line management model,” said Li Shuo.

Beijing Urban Construction Northern Group has undertaken the construction of numerous industrial park projects. For this purpose, a dedicated R&D team was established to continuously optimize product design, gradually summarizing and forming a series of competitive product lines. The Cuihu Science and Technology Park project team also actively participated, leveraging the advantages of the headquarters' full industrial chain. Through a series of scientific measures, including project planning and management systems, design management systems, and planning control systems, the team achieved unified optimization and improvement of the entire project lifecycle, ensuring that the project could proceed rapidly, continuously, and efficiently.

Precise and detailed project planning is the project team's "winning strategy." The project team emphasizes timely project planning and ensures that it is implemented and accurately implemented, thereby promoting high-standard construction and high-quality fulfillment of the project. The project planning for the artificial intelligence industrial park not only details the construction process for each stage but also showcases key processes and accurately records the number of workers, duration, engineering quantity analysis, and work efficiency data required for each process. For example, in the main labor force analysis and allocation table for the underground structure section, the number of workers in various trades such as steel reinforcement workers, carpenters, concrete workers, and steel reinforcement processing within the coverage area of Building 1's tower crane is clear at a glance, and the calculated daily workload for each worker is also clearly defined. “The construction industry is fiercely competitive. For our grassroots projects, the key to refined management is to determine the completion date and then refine project management and cost management down to each worker, each piece of machinery, and each material. The more detailed the calculation, the more it can help us gain more initiative in market competition,” said Li Shuo.

The project team adopted a strategy of concentrating forces for cluster warfare, a strategy that reflects profound management wisdom. The project department is responsible for three buildings with similar architectural structures and shapes. When choosing the construction sequence, the team, after careful consideration, decided to concentrate its efforts on completing the above-ground portion of one building after simultaneously completing the underground structure, and simultaneously starting the internal electromechanical pipelines and secondary structure construction. “We perform a full-process construction of one building in advance to expose any potential problems that may arise during the process,” explained Feng Lijie, the project's chief engineer. “Then, we can uniformly adjust the design optimization plan to avoid similar problems from occurring again in other buildings.”

From the current situation, this approach has indeed achieved its initial goals. For example, to improve the stiffening effect of H-section steel, stiffening plates are usually located on the sides of the steel beams. The conventional method is to make the stiffening plate flush with the flange and weld the stiffening plate to the web and upper and lower flanges. However, due to the weld angle, this welding method will inevitably cause the weld to protrude. To address this, the project team, in consultation with the manufacturer, reduced the width of the stiffening rib by approximately 8 millimeters. During welding, the weld at this location was chamfered to ensure weld continuity, reduce arc interruption, and improve weld quality and appearance.

Intelligent Construction: Empowering Product Quality Improvement and Efficiency

Relying on the strong technical support of the BIM studio of Beijing Urban Construction Northern Group, the project team built a BIM model covering all professions, including architecture, structure, electromechanical installation, and decoration. During the planning phase, the project team designed and optimized the site layout plan and developed the optimal solutions for site planning, traffic flow organization, and temporary building layout. “We used Navisworks software to perform full-professional collision checks, preemptively resolving more than 900 collisions between different professions,” said Feng Lijie.

In addition, the project's intelligent monitoring system can monitor various indicators on the construction site in real time. When an indicator exceeds the warning threshold, the system immediately issues a warning, reminding on-site personnel to take appropriate measures. The project team also conducted collaborative research on algorithm development with the "Money Cat" software, using AI technology to identify workers' violations and correct them in real time, thereby greatly reducing safety hazards. In on-site construction management, the project team also created QR codes for drawing and plan handover, converting the construction processes of important and complex nodes on site into easily understandable 3D visualizations for handover, improving construction efficiency and quality.

Learning Team: Inheriting the Spirit of "National Craftsmen"

Behind the refined management is the project team's determination to continuously build a learning team. Entering the "Zhiwei Study Room" in the project department's office area, various professional books are neatly arranged on comfortable tables and chairs, with the aroma of coffee and other beverages filling the air, providing a wonderful learning environment for project managers. Li Shuo introduced: “Our team has a relatively young average age, and many employees are eager to learn and improve. To this end, we have established this study room to fully enhance the overall learning atmosphere of the team.”

To comprehensively improve the "national craftsman" spirit and on-site practical management capabilities of managers, the project department frequently organizes vocational skills training activities. Not long ago, the project department organized a skills training session on secondary structure construction. At the event site, under the guidance of project manager Li Shuo, the drilling and cleaning group strictly followed the drawings to conduct on-site measurement and layout, accurately marking the drilling positions of the tie rods, and performing drilling and cleaning operations according to construction standards. The grouting group led by project chief engineer Feng Lijie also demonstrated extraordinary capabilities. After verifying the quality of the work of the drilling and cleaning group, they strictly followed technical requirements for glue mixing and injection, accurately inserting the processed tie rods into the grouting holes, ensuring that each tie rod was tightly bonded to the grouting and concrete wall surface. The steel reinforcement binding group led by Zhang Liying, deputy project production manager, paid more attention to testing the patience and skills of the participants. They followed the specifications of the column main reinforcement, spacing, and stirrup binding requirements, step by step, performing meticulous binding. Each completed column binding marked another step forward in everyone's basic skills.

It is precisely this meticulous project management approach and adherence to the spirit of 'national craftsmanship' that ensured the project team was able to achieve structural topping out ahead of schedule. Currently, while the Group's Cuihu Technology Park project team continues to advance the electromechanical and secondary structure construction of Building 1, construction of other buildings is also progressing steadily as planned. The project team will make every effort to ensure the project's completion and delivery by the end of next year, adding a technology park full of wisdom and vitality to the northwestern region of Beijing.