Information Center

Good news: two QC team results were rated as class I results in Beijing!

Recently, Beijing Urban Construction North Group has successively received the QC team achievement evaluation certificate from Beijing Construction Industry Federation. The two achievements of "improving the qualified rate of installation of steel truss floor bearing plate" and "reducing the probability of spitting during concrete pouring" have been evaluated as Class I achievements respectively.

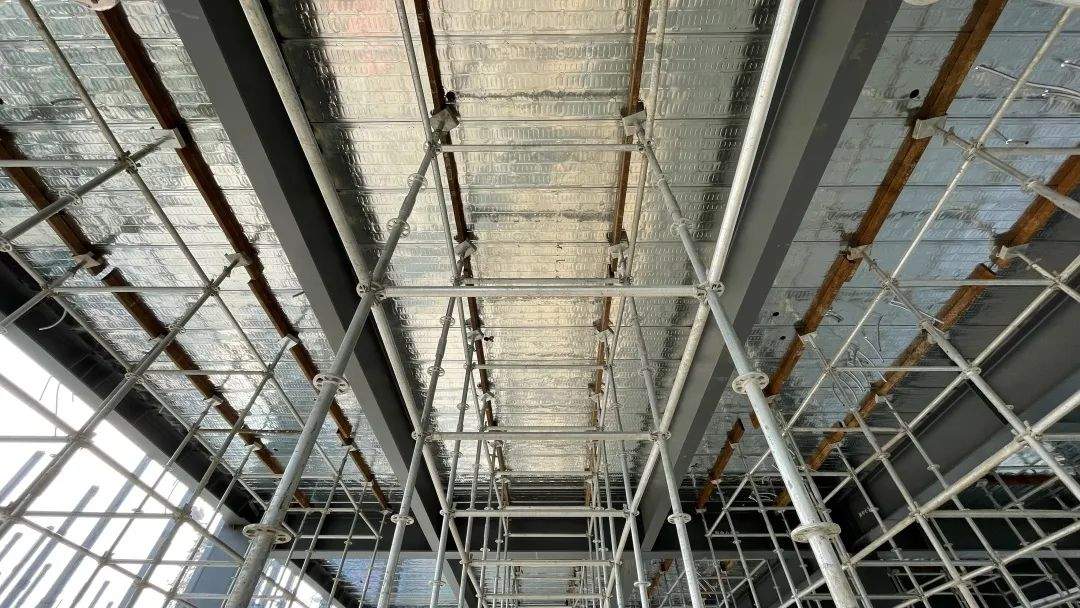

The group has carried out QC group activities of "improving the installation qualification rate of steel truss floor slab" in Tongzhou nine-year consistent school project. According to the on-site investigation and data analysis, the team members screened out the main influencing factors, and further improved the construction forming quality of the floor bearing plate by strengthening the acceptance of the finished products of the truss floor bearing plate, strictly controlling the quality of the floor bearing plate splicing and stud welding, and finally realized that the qualified rate of the one-time installation quality on site reached 97%. The project also continues the construction experience of the group's erqi factory project, using the way of mid-span supporting roof to ensure that the deflection deformation of large-span floor bearing plates such as classrooms and functional rooms meets the design requirements.

The group carried out QC group activities to "reduce the probability of concrete scattering" in bid section 4 of wangtan shed reform resettlement house. based on on-site investigation and data analysis, the group determined the main influencing factors causing scattering, formulated control measures such as adding ash stop valves, strengthened the supervision function of concrete pouring stations, guided pouring workers to strengthen the awareness of shielding and drainage, improved the forming quality of roof concrete, and was well received by the construction unit.

The quality management team of each unit of the group is active in the front line of construction and production, closely focusing on technological innovation, quality improvement, green construction and other work content, actively organizing and carrying out quality management QC group activities, which has played a positive role in improving the quality of the construction site and the quality of the project.

For a long time, the group has paid attention to integrating innovation concepts into the daily management of the enterprise. Through the incentive measures of "small innovation and big reward", the group encourages the majority of employees, especially young employees, to carry out post innovation and efficiency activities based on "meeting customer needs", so as to further improve product quality and management efficiency. Under the strong promotion of organizations at all levels of the enterprise, the awareness of independent innovation of the group employees has been continuously strengthened, the innovation ability of the enterprise has been greatly improved, and various innovation achievements have continued to emerge.