Information Center

Let Innovation "Hot" Group "Specialization and Innovation" Boost Key Project Construction

In March, Budeser, spring was busy at that time. Beijing Urban Construction North Group Equipment Installation Company Beijing City Sub-central Station Comprehensive Transportation Hub Project focuses on innovation and breakthroughs, releases scientific and technological vitality, applies "specialized, special and new" innovation achievements to engineering construction, and fully promotes high-quality performance of key projects.

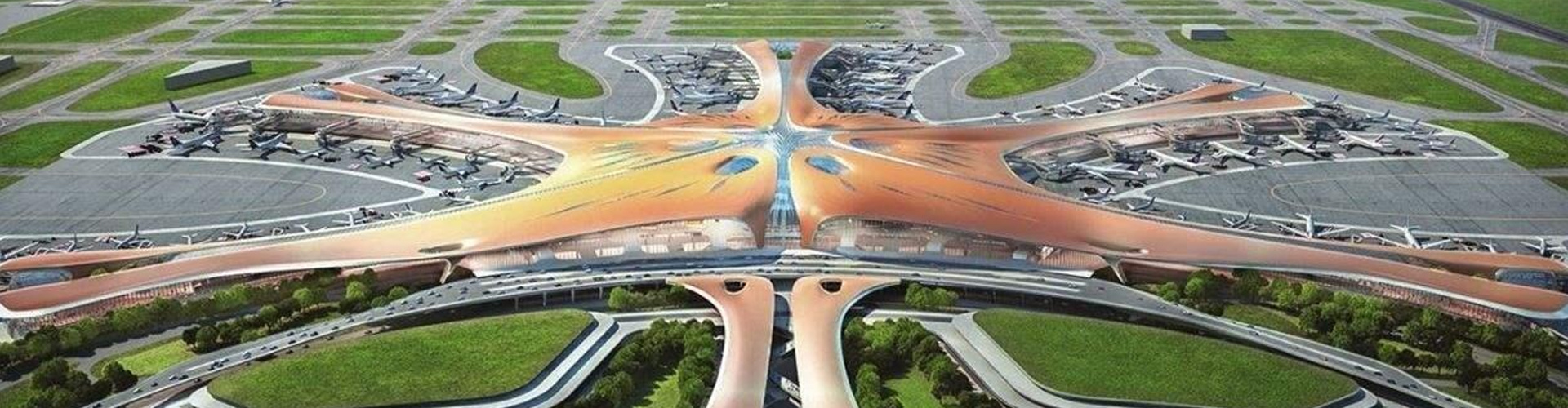

The Beijing Urban Sub-Central Station Comprehensive Transportation Hub Project is located in Yangtuo, Tongzhou. The building volume is equivalent to 7.1 Beijing South Railway Stations. It is a landmark project to promote the coordinated development of Beijing-Tianjin-Hebei. It will be connected to the Beijing-Harbin Railway, Beijing-Tangshan Intercity, and Metro 8 rail transit lines of different systems, including Pinggu Line, realize the interconnection of multiple transportation modes. After the completion of the project, it will become the largest underground integrated transportation hub in Asia and the model of integrated transportation hub of TOD station city in the new era. The Group Equipment Installation Company is responsible for the mechanical and electrical installation of the B0.5 floor of the 02 bid section of the project and the ramp pipe gallery of Furong Road. In the process of project construction, the project team releases the vitality of innovation, "research" for application, pays attention to the research of new methods, new processes, new materials and innovative equipment application, solves the difficult problems in the construction process with the power of science and technology, improves the efficiency and quality of project construction, and promotes the high-quality performance of key projects.

High-tech construction equipment

The project team actively explores the application of new equipment, and independently combines hydraulic cutting machine, chamfering machine and tapping machine to form an integrated processing machine for section steel support. The processed support and hanger structure is clean and elegant. In order to improve the installation quality and work efficiency, the project team actively explores welding automation and standardization, reduces the error and risk of manual operation, and studies and explores the use of new equipment such as cutting groove integrated machine and pipeline automatic welding machine. In order to improve the installation quality and work efficiency, the project team actively explores welding automation and standardization, reduces the error and risk of manual operation, and studies and explores the use of new equipment such as cutting groove integrated machine and pipeline automatic welding machine. The pipeline welding machine has a high degree of automation and can continuously carry out efficient and stable welding operations. In order to solve the magnetic attraction problem of stainless steel pipes, the project team has overcome the difficulties and developed a special track in combination with the working principle of the pipeline automatic welding machine to further achieve the goal of improving quality and efficiency.

High efficiency of construction materials

The project team considered the feasibility, speed, safety and other aspects of construction, combined with the advantages of traditional air ducts and fire separation, and innovatively introduced integrated fire air ducts. It adopts A- grade thermal insulation material, which has extremely high fire resistance and durability, and is the "safety guard" for maintaining construction projects ". The air-conditioning return duct adopts double-sided color steel composite duct, which is composed of double-sided color steel composite, with high strength and durability, beautiful appearance, good thermal insulation performance, and can effectively reduce energy consumption. Plastic-coated carbon steel clamping fire pipe adopts high-quality carbon steel material, after special treatment, the surface is coated with a layer of special material, which has high safety, corrosion resistance and pressure resistance.

High quality engineering management

The project team optimizes the process design, focuses on the site construction, and does a good job of self-inspection, mutual inspection and handover inspection to improve the construction quality. Each process adopts model first, carries out red line inspection every month, strengthens quality acceptance, and ensures the realization of the double-zero goal of "zero" error and "zero" error.